Material handling is an essential component of the logistics and transportation sectors, particularly for truck drivers, who have a crucial responsibility for efficiently and securely transferring cargo. Adhering to appropriate safety procedures while handling materials not only safeguards the drivers but also reduces the likelihood of accidents, injuries, and harm to goods. This article explains the crucial safety rules that truck drivers must follow in material handling, with a specific emphasis on the utilization of gravity conveyors.

1. Pre-Trip Inspections

Prior to commencing any journey, truck drivers should perform comprehensive pre-trip inspections. This entails inspecting the state of the vehicle, including its brakes,

tires, lights, and other essential components. Maintaining the truck’s optimal condition can mitigate mechanical malfunctions that may lead to mishaps when handling materials.

Image by

Freepik2. Proper Use of Personal Protective Equipment (PPE)

Truck drivers are required to utilize suitable Personal Protective Equipment (PPE) when dealing with materials. This entails donning gloves, safety glasses, steel-toed footwear, and high-visibility vests. Personal Protective Equipment (PPE) plays a vital role in safeguarding individuals from potential dangers, including sharp edges, heavy objects, and situations with low visibility.

Image by

Freepik3. Safe Loading and Unloading Practices

Loading and unloading are hazardous procedures that are prone to numerous accidents. When utilizing gravity conveyors, it is important to include extra safety measures:

● Make sure you install the conveyor in a flat and stable area and firmly fasten it to the truck or loading dock to avoid any displacement.

● Ensure that the gravity conveyor is devoid of any faults and operating efficiently.

● Employ stops or brakes on the conveyor system to regulate the velocity of materials and avert their uncontrolled displacement.

● Prioritize the loading of larger objects initially to ensure stability and balance on the conveyor.

Drivers must also verify that the truck is parked in a flat area, the brakes are on, and the load is evenly distributed to avoid the truck tipping or the cargo shifting during transportation.

Image by

Freepik4. Understanding Load Limits

Truck drivers must possess knowledge of their vehicle’s load capacity and never surpass it. Exceeding the weight limit of a truck can result in the driver losing control, the brakes malfunctioning, and the vehicle experiencing greater damage and deterioration. Efficiently controlling the weight of the cargo guarantees improved handling and enhanced safety during transportation. Similarly, it is important to adhere to the load restrictions of the gravity conveyor in order to prevent any potential structural failure.

Image by

Freepik5. Ensuring Load Safety

Ensuring the proper fastening of loads is essential to avoid any displacement during transportation. Unrestrained cargo can move, causing vehicle instability and even accidents. Motorists should utilize straps, ropes, and load bars to fasten and stabilize materials. Frequently monitoring the load during transportation can also aid in promptly detecting any possible problems. When utilizing gravity conveyors, it is important to guarantee that things are firmly positioned and will not dislodge or roll off throughout the handling process.

Image by

Vecteezy6. Ergonomic Practices

Truck drivers frequently perform manual handling jobs that have the potential to cause musculoskeletal injury. Implementing ergonomic measures, such as utilizing leg muscles instead of the back for lifting, refraining from twisting movements during lifting, and employing mechanical assistance whenever possible, will greatly diminish the likelihood of sustaining injuries. Gravity conveyors can mitigate physical exertion by facilitating the movement of items with less manual labor; however, it is crucial to employ correct technique to prevent injury.

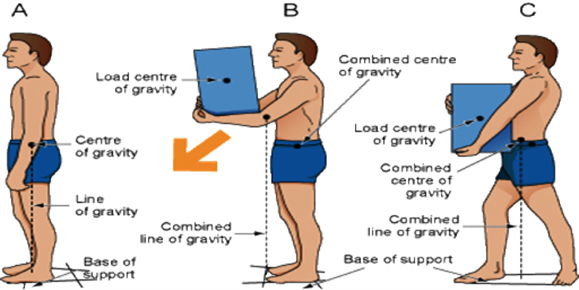

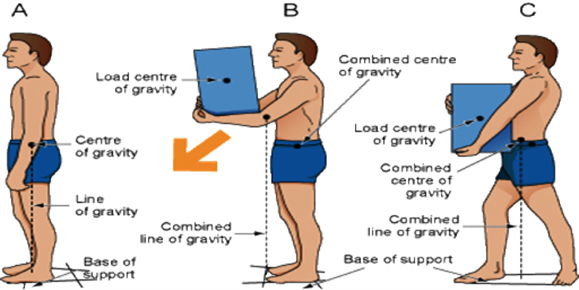

The picture below shows how holding a load changes a person’s balance by showing how the center of gravity and line of gravity move. Center of gravity is where the body’s (or an object’s) weight is evenly spread. For a standing person, this is usually around the middle. The line of gravity is a made-up straight line that goes from the center of gravity to the ground. People usually put their weight on the spot between their feet when they stand. This is their base of support. The person must be able to keep their balance if their center of gravity is above their base of support and their line of gravity falls inside their base of support.

The center of gravity of the person and the load move when they carry it, especially when it is far away from their body. This can make it harder to balance and stay stable. When someone is standing without anything on their back, their center of gravity is in the middle of their body, and their line of gravity goes inside their base of support. This makes for a stable and balanced position. When you hold something close to your body, your total center of gravity stays at the base of support. This helps you stay balanced and stable. Holding a load away from the body, on the other hand, moves the combined center of gravity forward. This could make the person unstable and increase the chance that they will lose their balance and fall.

It is important to keep the combined center of gravity within the base of support by holding loads close to the body. This will help you stay balanced and reduce the risk of injury. When you move the weight away from your body, your combined center of gravity goes forward. This makes you less stable and increases your risk of falling and muscle strain, especially in your lower back. Understanding these ideas is important for ergonomics and workplace safety, because using the right lifting methods can greatly lower the risk of musculoskeletal injuries that are common in jobs that require lifting heavy things by hand. These ideas can help you keep your balance when doing normal things like carrying food or moving furniture. They can also lower your risk of injury, make you more stable, and improve your long-term musculoskeletal health.

Image from

Creative Commons7. Awareness of Surroundings

Situational awareness is a key part of avoiding accidents. When driving, one should be extremely aware of their surroundings, including other vehicles, pedestrians, and any potential hazards on the road or at the site where products are being loaded or unloaded. Using mirrors and, if available, backup cameras can help you see better and stay safer. While using gravity conveyors, it is important to make sure that there are no obstacles in the area around the conveyor and that everyone knows how it works.

Image by

Vecteezy8. Communication

It’s very important that everyone involved in moving the materials can talk to each other clearly. This includes communicating with warehouse staff, other drivers, and dispatchers. Good communication cuts down on false information and makes sure that everyone knows what their tasks are and what risks might be involved. When using gravity conveyors, communicate with colleagues about the movement of materials to coordinate efforts and avoid accidents.

Image by

Vecteezy9. Adherence to Regulations

Truck drivers are required to abide by safety regulations and laws set forth by organizations like the Department of Transportation (DOT) and the Occupational Safety and Health Administration (OSHA). To maintain a high level of safety, it is important to stay up-to-date on the latest laws and best practices. In this case, following rules that are especially made for using machines for moving things would be included.

Image by

Vecteezy10. Continuous Training

Truck drivers need to keep learning about safety rules and techniques, so they need to get training and guidance all the time. Some of the things that might be covered in regular training sessions are getting used to new tools, following new rules, and using current safety measures. In order to make sure that gravity conveyors are used safely and effectively, they must be properly maintained and used with the right training classes.

Image by

VecteezyTruck drivers must strictly follow specified rules when handling materials to guarantee their safety and the safety of others. When utilized properly, gravity conveyors can increase productivity and safety in operations, but they also need to be set up and maintained properly. Risks can be reduced by incorporating safety procedures such as load fastening, PPE use, and pre-trip checks. Constant training improves safety by keeping drivers informed about new developments in technology and best practices. Setting these rules as a top priority promotes a safer workplace and helps the transportation sector become more dependable and effective.